- Calcium Carbide

- Calcium Cyanamide

- Dicyandiamide

- Electronic grade Dicyandiamide

- Cyanamide

- Creatine monohydrate

- Aminoguanidine bicarbonate

- Sarcosine

- Creatine Monohydrate

- Creatine

- Creatine HCL

- Creatine Nitrate

- Creatine Ethyl Ester Hydrochloride

- Creatineorotate

- Dicreatine Malate

- Tricreatine Malate

- Di-creatine Citrate

- Tricreatine Citrate

- Creatinine

- Creatine Alpha- Ketoglutarate

- Creatine Gluconate

- Creatine Ethyl Ester Malate

- Creatine Pyruvate

- Magnesium Creatine Chelate

- Creatine Phosphate

- Dicyandiamide-Industrial Grade

- Guanidineacetic Acid

- β-Guanidinopropionic acid

- Guanidine Hydrochloride

- Guanidine Carbonate

- Guanidine Nitrate

- Nitroguanidine

- 1-Methyl-3-Nitroguanidine

- Dicyandiamide-High Purity

- Micro-Dicyandiamide

Position: Home > Products

Position: Home > Products

Product name: Dicyandiamide

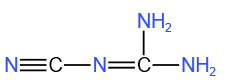

Molecular formula: C2H4N4

Structural Formula:

CAS: 461-58-5

Molecular weight: 84.08

Dicyandiamide is a dimer of cyanamide and a cyano derivative of guanidine. White crystalline powder, soluble in water, alcohol, ethylene glycol and dimethylformamide, practically insoluble in ether and benzene. Nonflammable. Stable when dry.

The main uses are: (1) as a guanidine salt, melamine raw materials. By reacting Dicyandiamide with an acid, various guanidine salts can be prepared. Phenylmelamine, obtained by the reaction of Dicyandiamide and phenyl nitrile, is an intermediate for coatings, laminates and molding powders. (2) As a dye fixing agent, Dicyandiamide resin prepared by the reaction of Dicyandiamide and formaldehyde can be used as a dye fixing agent. (3) Dicyandiamide fertilizer, Dicyandiamide compound fertilizer can control the activity of nitrifying Chemicalbook bacteria, adjust the conversion rate of nitrogen fertilizer in soil, reduce nitrogen loss and improve fertilizer use efficiency. (4) as a fine chemical intermediate. In medicine for the preparation of guanidine nitrate, sulfonamides and other drugs; Also used to produce thiourea, nitrocellulose stabilizer, rubber vulcanization accelerator, steel surface hardener, artificial leather filler, adhesives and so on. 5-azacytosine, a medical intermediate, can be obtained by the reaction of Dicyandiamide and formic acid. Dicyandiamide products have a wide market.

Product Process:

Water or mother liquor is pumped into a stirring tank, ground by lime nitrogen, quantitatively and uniformly added into a slurry preparation tank for full stirring, so that the lime nitrogen is completely hydrolyzed to generate cyanamide calcium liquid, and then the hydrolysate is sent into a carbonization tower by a slurry pump, and completely contacts and reacts with carbon dioxide gas (kiln gas) which enters the carbonization tower after being compressed from a lime kiln, so as to complete the decalcification process of the lime nitrogen aqueous solution. adding the feed liquid after the hydrolysis decalcification reaction is completed into a belt filter to filter out impurities of hydrolysis and carbonization in the lime nitrogen and calcium carbonate solid generated in the carbonization process to obtain pure Cyanamide solution; the Cyanamide aqueous solution is pour into a polymerization kettle, heated to 70 DEG C by steam, and that PH value is adjust to about 10 to complete the polymerization process and generate Dicyandiamide. then putting the Dicyandiamide aqueous solution into a suction filter barrel, filtering out impurities such as lime and the like generated in the polymerization process, and then filtering the Dicyandiamide aqueous solution by a diatomite filter to obtain a pure Dicyandiamide solution; pouring the pure Dicyandiamide solution into a crystallizing pot, cooling and crystallizing the Dicyandiamide aqueous solution with low temperature water from a freezing station, and precipitating Dicyandiamide solid in the solution; discharging the solution in the crystallization pot, filtering by a suction filter barrel, wherein the Dicyandiamide crystal is dried by a centrifugal machine, and then is dried by a fluidized bed dryer to obtain a Dicyandiamide finished product; The filtered Dicyandiamide mother liquor is sent to the slurry preparation tank for hydrolysis of lime nitrogen to complete the closed circulation of the process system.

The purity of qualified Dicyandiamide is more than 99.5%.